EuroTower® The sheet metal storage clou

Tower storage with euroFLAT® system standard pallets

The EuroTower®

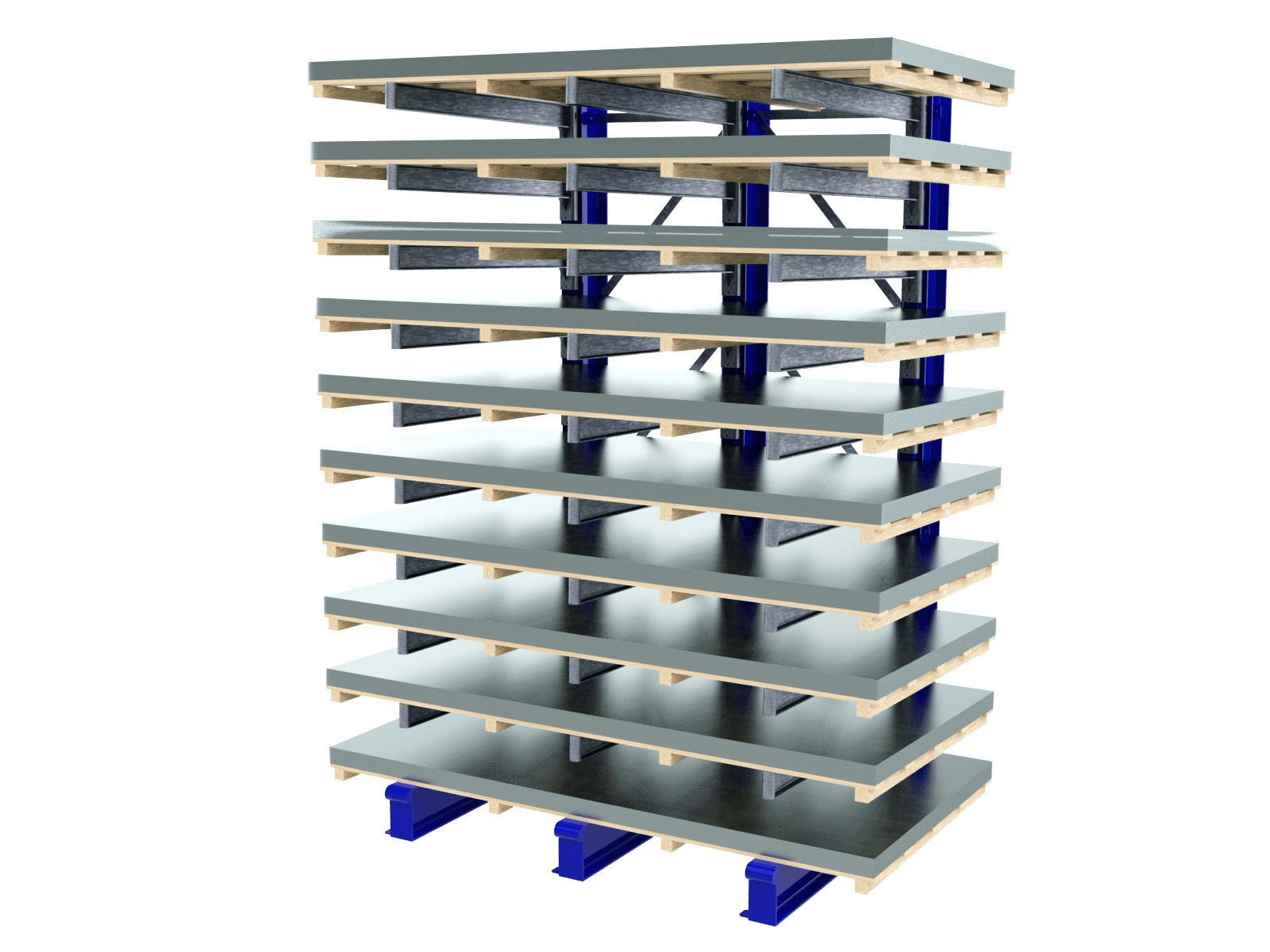

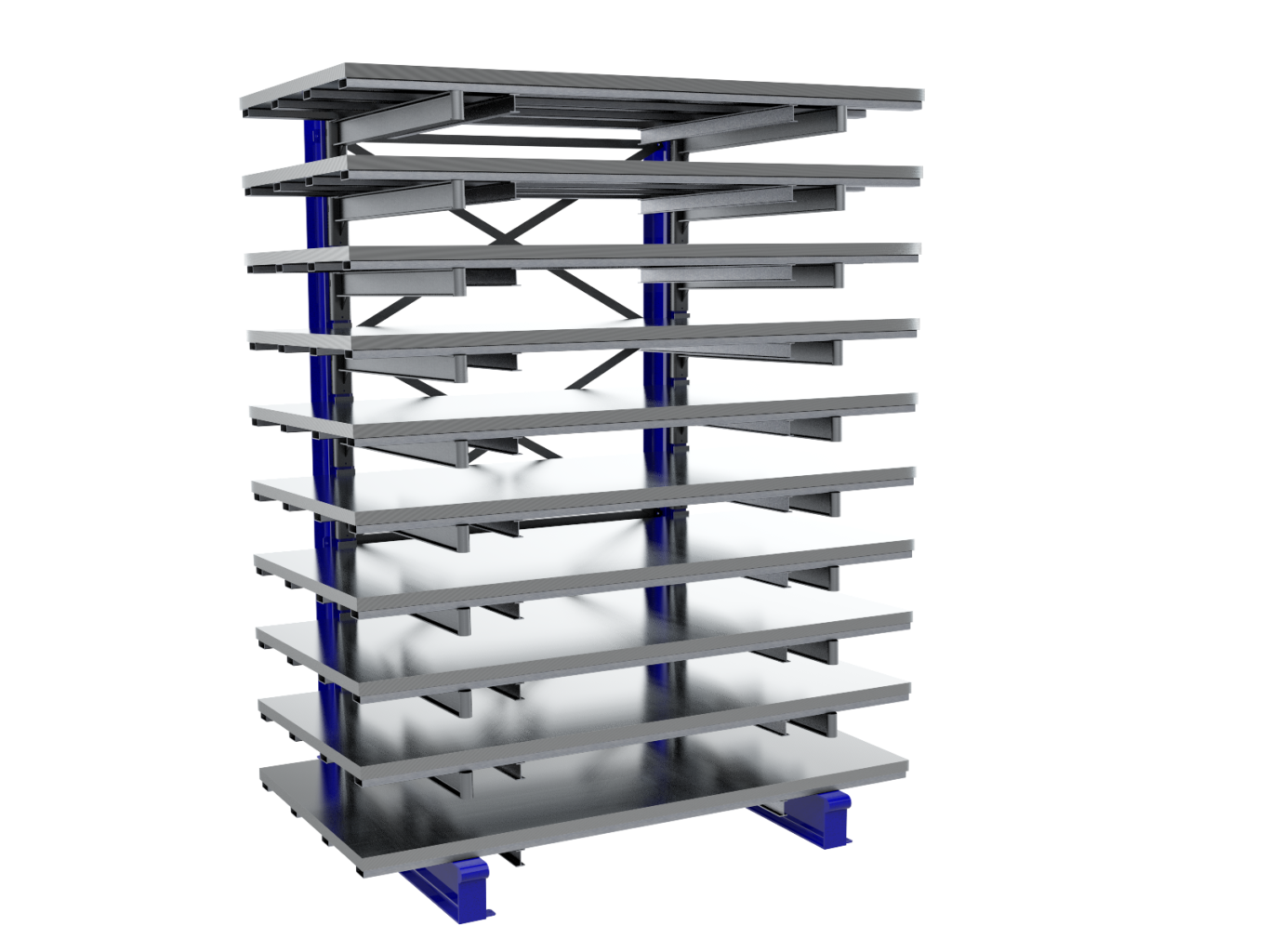

The EuroTower® combines the advantages of the ArmStrong® BN and the euroFLAT® Sheet metal load carrier for sheets and sheet metal packages. The EuroTower® supports the material flow, reduces space requirements, ensures more ergonomic work processes and safety when working in the sheet metal storage area.

Reduction of storage costs through optimal storage density and ideal material flow

The EuroTower® from the house of storemaster® is a well thought-out, cost-effective and practical standard rack for sheet metal storage with the matching load carriers. euroFLAT®. On the one hand, the solution enables space-saving storage of sheets and sheet packs. On the other hand, the rack has the ideal dimensions for compact storage of flats. Storage and retrieval are also extremely simple. Because the euroFLAT® does not have any interfering contours all around, e.g. for smooth loading on cut-to-length lines.

The load capacity per load carrier is 3,000 kg and thus provides a standard market capacity for your sheet metal storage. You receive the euroFLATs® optionally with pluggable stops. On the EuroTower® they contribute to the prevention of accidents during loading and unloading of the racking system.

The easy and effective access to the material in your sheet metal storage standard rack saves you ways and removal times. With the high storage density and practical features of the EuroTower® reduce your storage costs and promote the flow of materials.

EuroTower® incl. universal system exchange pallet euroFLAT®.

patent (DBGM) simply ingenious universal - for any application.

Product advantages at a glance

Sheet metal storage standard shelf for small, medium, large and maxi size sheet metal packages on euroFLAT® System pallet with a permissible load capacity of 2,500 kg or 3,000 kg.

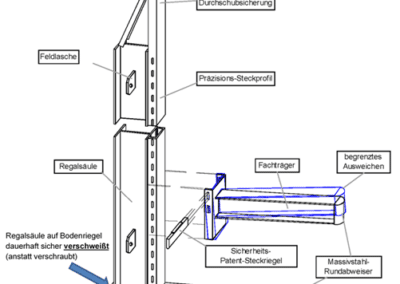

- Patented plug-in bolt system with form-fit, i.e. easily detachable, tool-free adjustable shelf support safety suspensions (no wedging or jamming)

- Semi-circular solid steel edge protection on foot beams and lattice girders

- Height-adjustable shelf supports in 75 mm plug-in grid

- Racking column with push-through safety device, locked against overload due to misuse, stat. Design, deflection and increased tilt resistance in accordance with RAL-RG 614 of the Gütegemeinschaft für Lager- und Betriebseinrichtungen (Quality Association for Storage and Operational Equipment).

- Floor surface pressure < 50 kg/cm²

- Foot beams with dowel clips for on-site floor anchoring (tilt-resistant without tension-proof anchoring to the floor by exclusive storemaster® Design features - simple dowelling optional only against displacement)

- Stand painted to RAL 5002 ultramarine blue

- Bandages chromated

Compartment girders hot-dip galvanised against abrasion according to DIN EN ISO 1461 - incl. floor anchors, assembly and operating instructions, as well as system type plates with manufacturer and shelf data in accordance with BG regulations.

- Quality and quality assurance in accordance with RAL-RG 614 quality and testing regulations.

Technical details

In order to ensure the stability of cantilever racks of the usual design, a tension-resistant floor anchorage must be provided. This requires a suitable floor condition, which is very often not given accordingly.

This circumstance is taken into account by storemaster® through constructive measures that ensure tilt resistance even without any floor fixings.

However, the shelving should still be fixed against displacement by fork-lift truck impacts, e.g. by means of simple drive-in anchors. If the condition of the installation surface does not allow this satisfactorily either, storemaster® bracing elements in the floor area make it considerably more difficult for fork-lift trucks to move and deform the shelving components.

Only in outdoor areas with roof and wall must the installation be carried out on concrete slabs or corresponding foundations in accordance with the building regulations, as here a tension-resistant ground anchorage is mandatory due to occurring wind and snow loads.

Climate-friendly storage without wood

With the EuroTower® you are well on the way to climate-neutral sheet metal storage. The standard sheet metal storage rack with metal load carriers is naturally germ-free and has a surface that is not susceptible to external influences.

The manufacture of wooden pallets and other wooden loading or storage equipment involves a considerable amount of processing to keep the natural material stable and pure in a storage environment. This processing involves the use of chemicals and chemical processes. The removal of pests such as insects and fungi additionally affects the environment. However, if natural materials such as wood are used, such an application cannot be dispensed with, because pests can not only infest pallets, but also goods and people. Likewise, the load-bearing capacity and stability of load carriers suffer under microorganisms.

The euroFLAT®-load carriers also have other advantages for the environment: they are suitable for use as exchange pallets with your sheet metal supplier. In this way, you make a greater contribution to the repeated and long-term usability of your storage equipment.

More safety for storage and transport

When storing flatracks in the metalworking industry, hazards can arise for the workforce when handling heavy loads. If load carriers tip, fall down or slide, you risk industrial accidents. That's why it's especially important here that sheet metal and sheet packs are stored safely. Also for this reason, the EuroTower® sheet metal racking is the best alternative to conventional storage on wood. It safely stores loads of up to 3,000 kg per load carrier. Your team can therefore move safely and efficiently between the tried-and-tested sheet metal racks. Access to your material is also quick and easy.

At the same time, the standard shelf in various designs also ensures clarity, order and cleanliness. Here you have direct access to the right material without having to clear and search, and you can supply your machines in no time at all. The EuroTower® delivers storage density, material flow, environmental friendliness and the reduction of your storage costs for little money.

The automatic alternative

storemaster® ShuttleMaster AUTOMATIC

The new highlight in automatic sheet metal processing - finally for less money.

ingeniously simple | efficient | highly flexible | modular

Sheet metal storage automation with growth potential - successively expandable to up to 1,000 sheet metal types - with up to 10 machines - conventional sheet metal processing active in parallel.

Ideal also for the Pre-picking of sheets for continuous processing of machine follow-up orders without the continuous provision of whole sheet packs of changing sheet types.

The Starter Kit: production-integrated with 20 change places (10 temporary + 10 in buffer) from 150.000,00€ handed over ready for operation - any further storage space that can be integrated in the ShuttleTower® from 1.000,00€.