Call us

or simply contact us via WhatsApp!

mo - fri 8:00 a.m. - 6:00 p.m. (MET)

opt. with integrated crane vacuum technology

Professional steel construction with a 20-year guarantee

The storemaster® Original from 2000

20 years warranty

from 13.417,00€

excl. VAT

Delivery time: 10-12 weeks

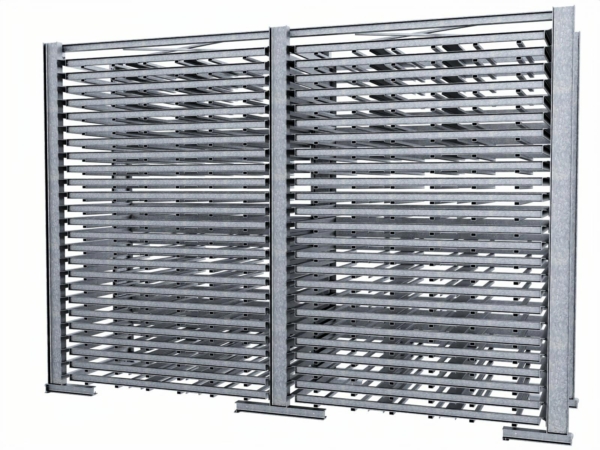

One-man sheet metal handling compact station without external crane or forklift traffic. Multi-task drawer system for permanent or temporary loading of sheet metal packages in cassette-flat system pallets.

One storemaster®-innovation from the year 2000 with 20 year guarantee.

Delivery: free delivery within Germany

The original from 2000 - an investment for generations.

Sheet metal storage drawer system with swivelling drawer runners, optionally lockable, high load-bearing, permanently lubricated block hinges permanently fix the swivel-out panels in their height position, permanently offset-free rail transition between block and swivel rails, as they are welded - not bolted! Occupational safety in accordance with internationally applicable standards, system block-mounted ready for operation - optional electrified pull-outs. Torsion-resistant L-shaped upright frame construction for permanent perpendicularity ► 20-year functional guarantee; automatic locking devices secure the rest and working position of the drawers without manual operation; mechanical locks for drawers with a payload of ≤ 2,000 kg; servo spring patent facilitates the extension of heavy-duty drawers with a payload of ≥ 2,500 kg.

Sheet metal bearing pull-out system with swivelling pull-out roller cheeks, permanently offset-free rail transition between block and swivel rails, as they are welded - not bolted! Torsion-resistant L-frame upright construction for permanent perpendicularity ► 20-year functional guarantee - an investment for generations.

Functional safety with swivelling pull-out side-panels:

The roller flange guides on the running surfaces of the rails alone reliably secure the drawers against falling without the need for additional BG-compliant measures in the event of additional lateral forces (e.g. forklift impacts). Strong magnets automatically fix the swivelled-out pull-out roller side panels in their 90° position without the need for BG-compliant mechanical and manual locking devices.

The storemaster® - Roller convenience for systems with drawer runners:

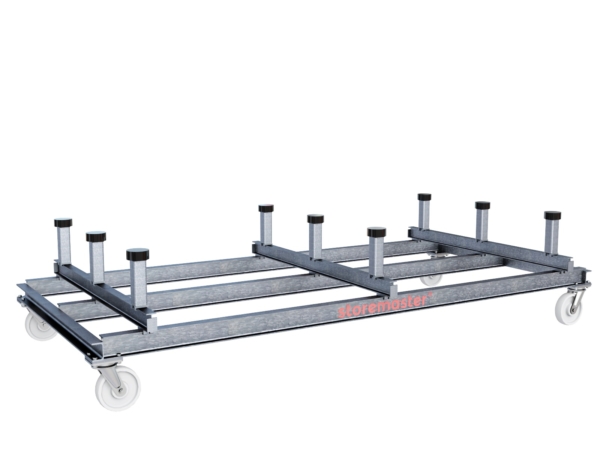

Each swap-body trolley runs on 8 bearings in special smooth-running ball bearings on chromated solid steel flanged wheels (no lightweight sheet metal castors or ball bearings misused as wheels) with double axle bearings, safely and tilt-free on hot-dip galvanised (10 times more abrasion-resistant than painted surfaces), smooth running rails without dirt pockets, as there are no upward or downward folds. Perfect fall protection with automatic function in accordance with UVV with swivelling design. Special heavy-duty precision block hinges with permanent lubrication ensure a permanent, maintenance-free rail transition into the pull-out area with swivelling pull-out side-panels.

Work safety and accident prevention (occupational safety) in accordance with international standards:

storemaster® fulfils the following UVV occupational safety requirements, which cannot be rectified by reworking, without which commissioning of the product would permanently jeopardise the BG insurance cover: Exclusion of human error through failure to actuate safety devices:

without loss of rolling comfort - without manual locking device

The original from 2001

storemaster® Slide-in patent

prof. steel construction engineering

(rigid connections, 5-fold kink safety)

Resistant to forklift impacts

20 years warranty

excl. VAT

To the details This product has multiple variants. The options may be chosen on the product page

Depalletiser and cassette loader

storemaster® Innovation from 1997

excl. VAT

To the details This product has multiple variants. The options may be chosen on the product page

System pallet loader

storemaster® Innovation from 2023

excl. VAT

To the details

Universal warehouse management software

excl. VAT

To the detailsstoremaster GmbH & Co. KG

Reihekamp 1

30890 Barsinghausen

Germany

Dipl.-Ing. Dieter Karl Artur Paul

You can find more information on calculating quantity discounts and payment methods here:

Contact us for customised solution concepts: