Coillager

CoilStore® horizontalSlit strip storage system for ring widths up to 600 mm

on slide-in system pallet up to 10 t shelf load

from 2.615,00€

excl. VAT

Delivery time: 10-12 weeks

Heavy-duty handling storage system for slit strip stacks on specially designed load carriers/pallets for angle-on-angle forced insertion into special storage towers with high storage density. A slat-band shelving system for forklift operation with a permissible shelf load of up to 10 t, impact-, abrasion- and wear-resistant thanks to hot-dip galvanisation in accordance with DIN EN ISO 1461. The high flexibility of the slide-in system lies in its shelf height grid of 300 mm for optimum adaptation to the constantly changing stack heights. Standard load capacity 5 tonnes.

Delivery: free delivery within Germany

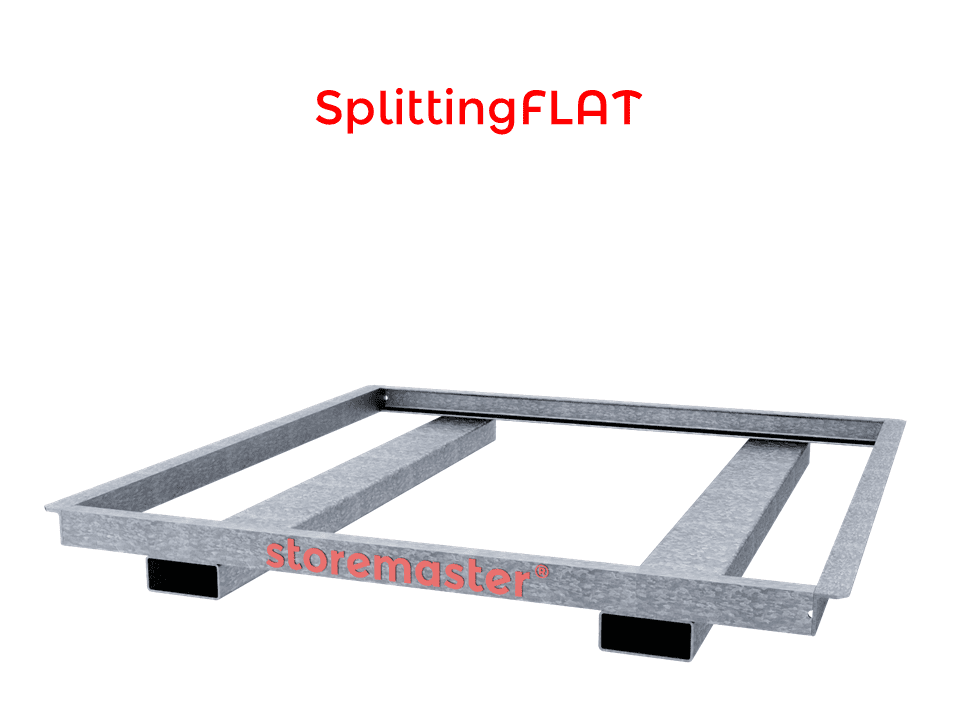

CoilStore® horizontal Slit strip storage system

We have compiled the following downloads for this product:

Herstellerinformationen

storemaster GmbH & Co. KG

Reihekamp 1

30890 Barsinghausen

Germany

Verantwortliche Person in der EU

Dipl.-Ing. Dieter Karl Artur Paul

Frequently asked questions about coil storage

Does not apply to already reduced offers.

You can find more information on calculating quantity discounts and payment methods here:

Free delivery within Germany from goods value ≥ 5000€ CIP

Within the EU EXW ex works

Outside the EU EXW ex works plus 5% foreign flat rate

Contact us for customised solution concepts: