ShuttleTower® sheet metal storage

The original from 2001

storemaster® Slide-in patent

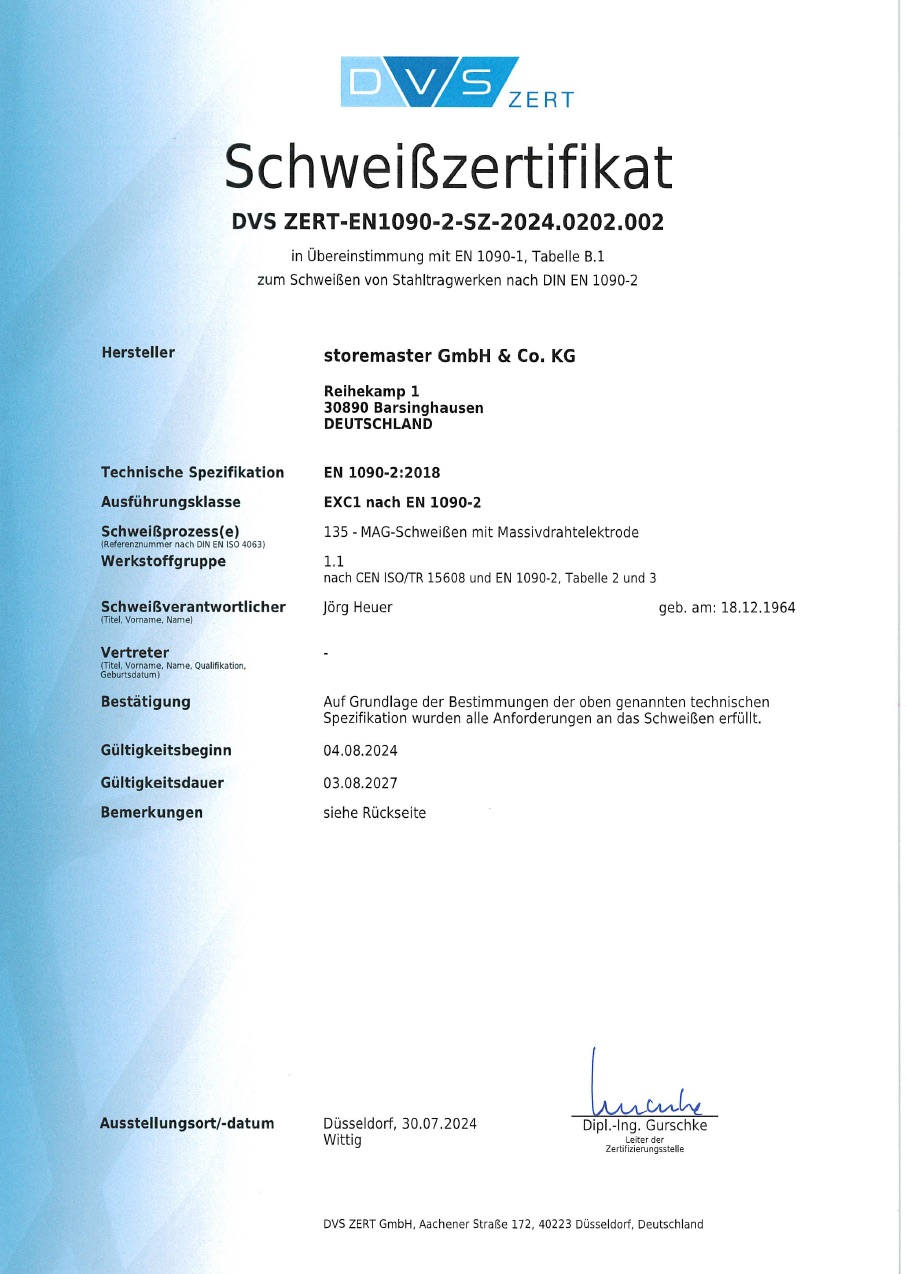

prof. steel construction engineering

(rigid connections, 5-fold kink safety)

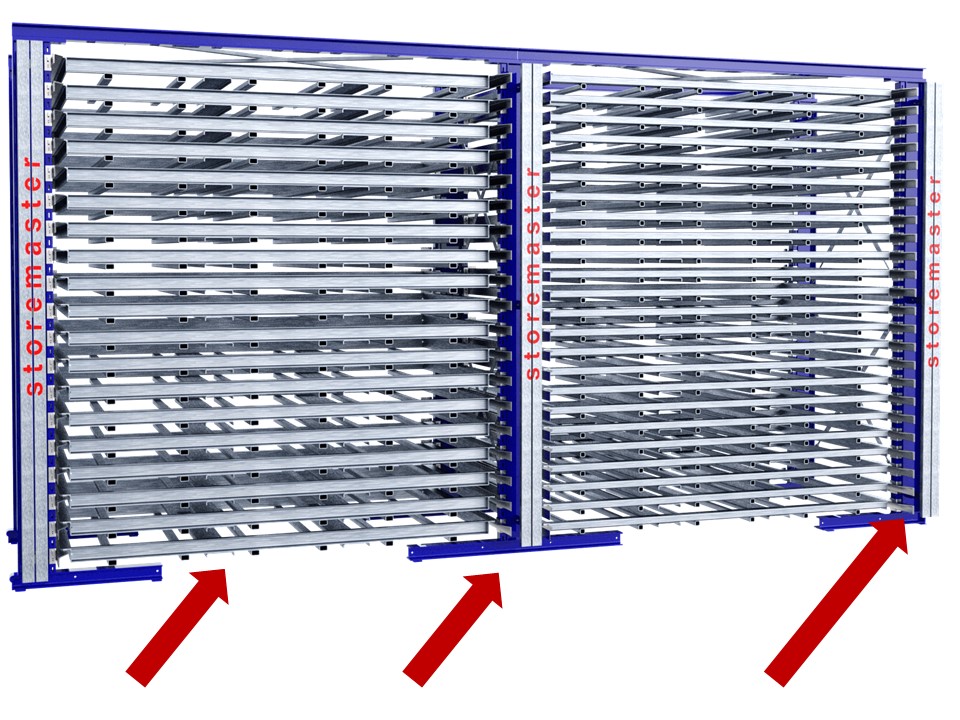

Resistant to forklift impacts

20 years warranty

from 5.793,00€

excl. VAT

Delivery time: 10-12 weeks

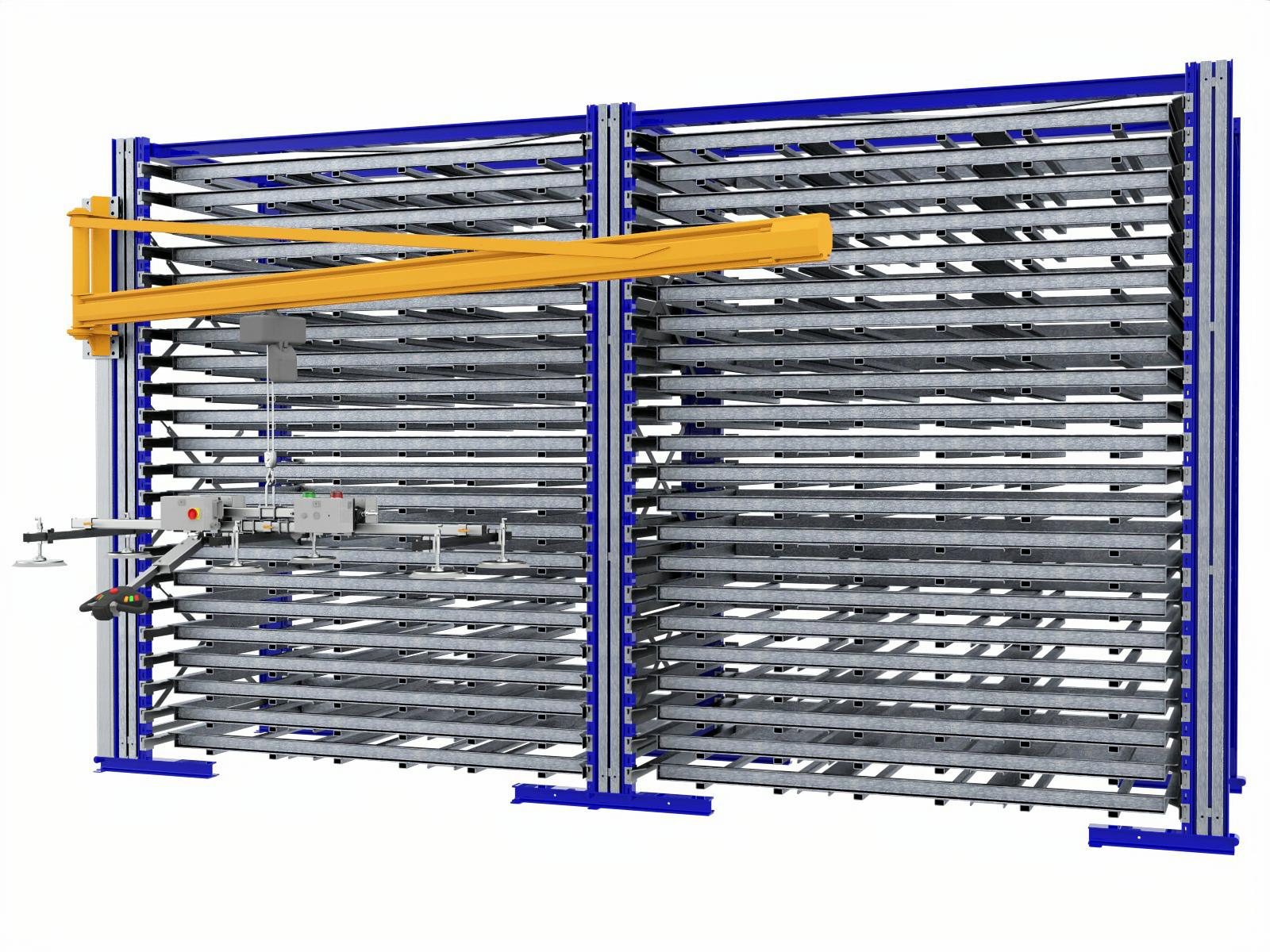

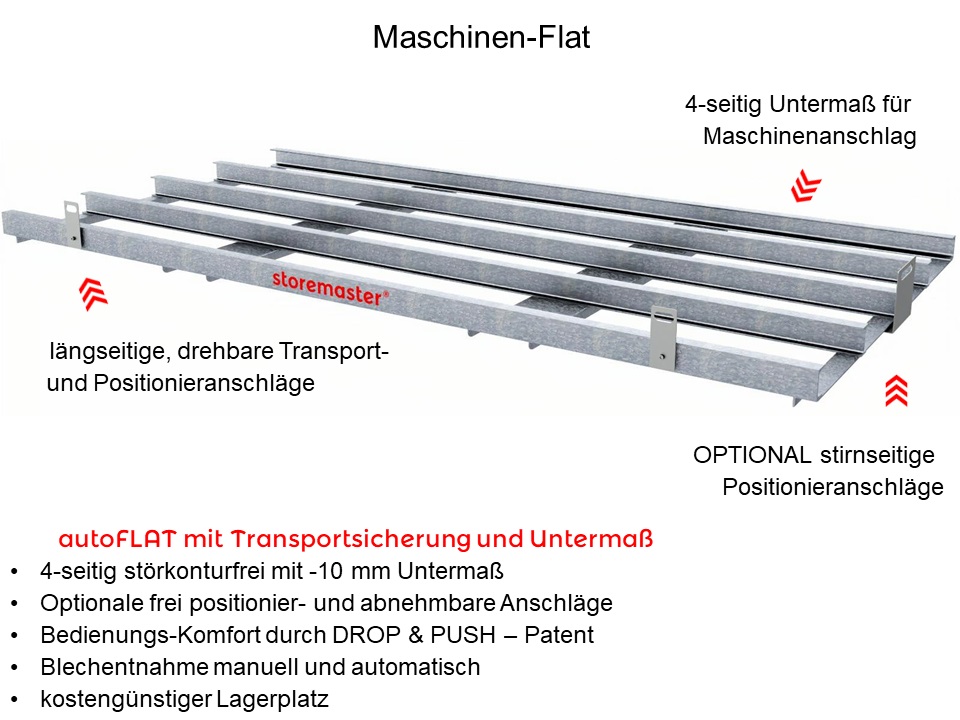

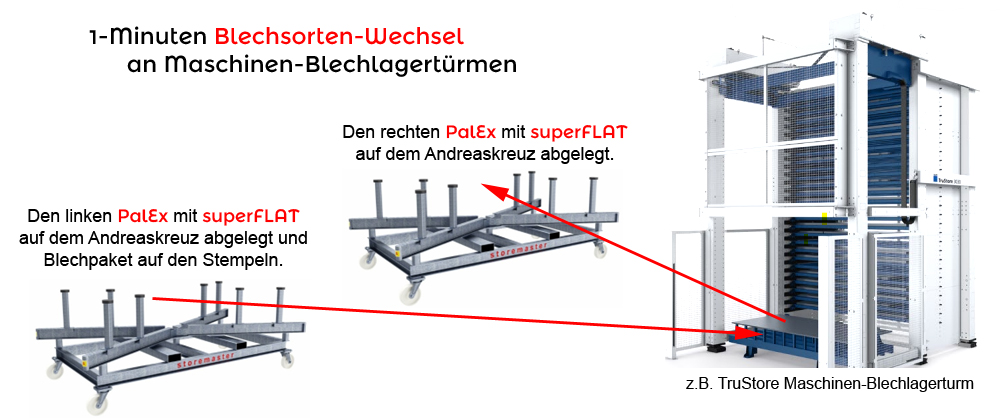

With the collision-free storemaster® Angle-on-angle constrained guide comfort insertion patent and the storemaster® Safety retraction stroke of approx. 200 mm. BG safety thanks to rigid connections and 5-fold safety against buckling (incl. 1st shelf test in accordance with DIN EN 15635). For semi-automatic and fully automatic sheet feeding on all machines. Uprights and load carriers optimised as required as superFLAT-classic, smartflat, superFLAT-plus, masterFLAT or autoFLAT in an impact- and corrosion-resistant, hot-dip galvanised design - resistant to forklift impacts. Durability and sustainability to the highest degree thanks to Quality No. 1.

➠ Optionally with integrated crane vacuum technology.

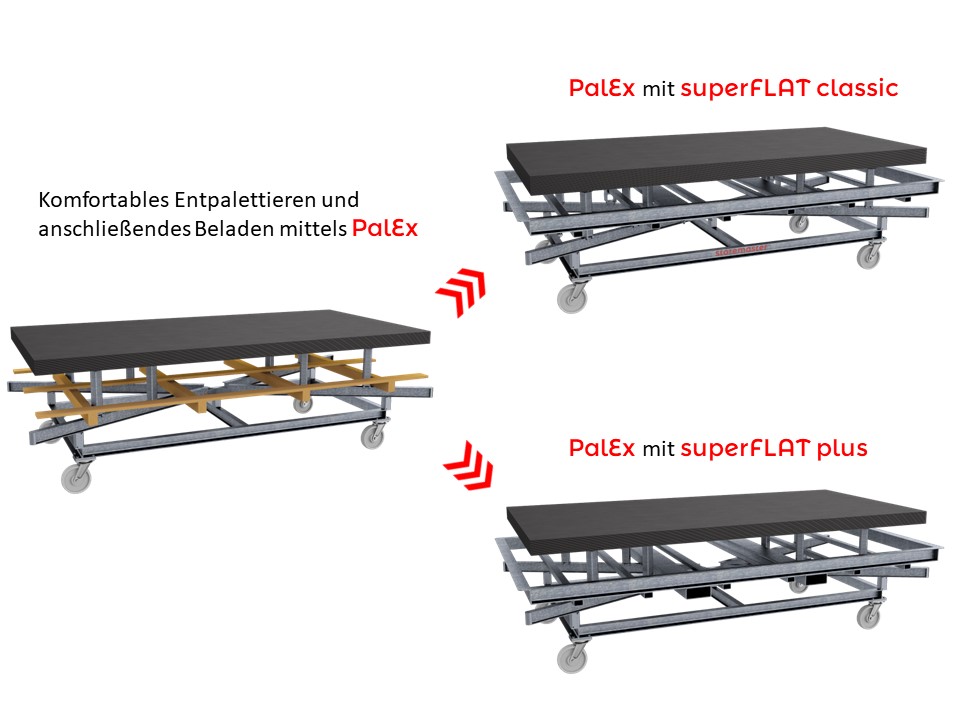

The storemaster® depalletiser is used to depalletise and load the system pallets PalEx®.

Click here... for the design of the ShuttleTower® and the individual load carriers in detail.

Load carrier suitable for:

- Liftmaster, Sheetmaster, Loadmaster

- Bystronic, Amada, automatic storage towers

- Manual crane vacuum sheet removal technology

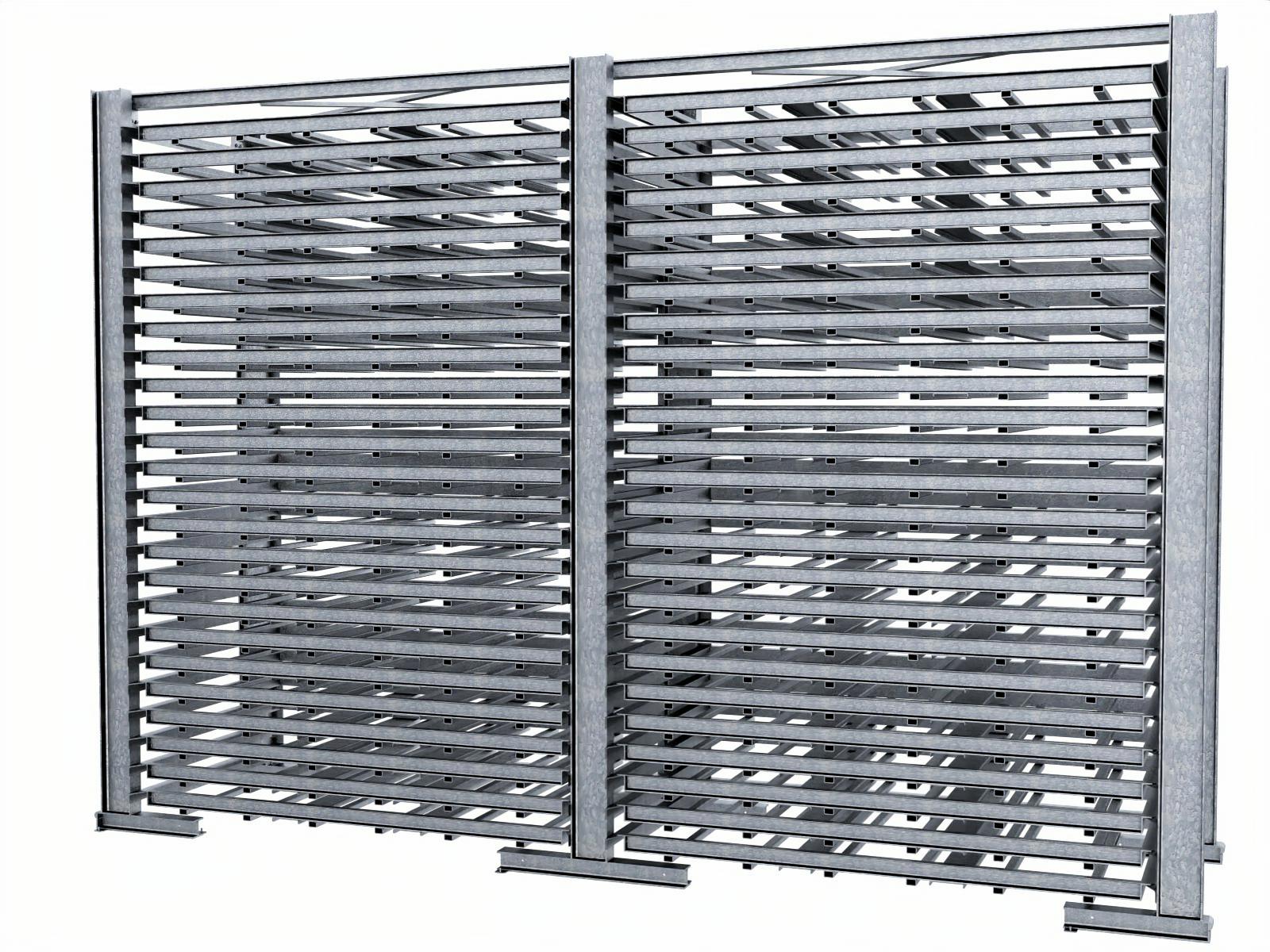

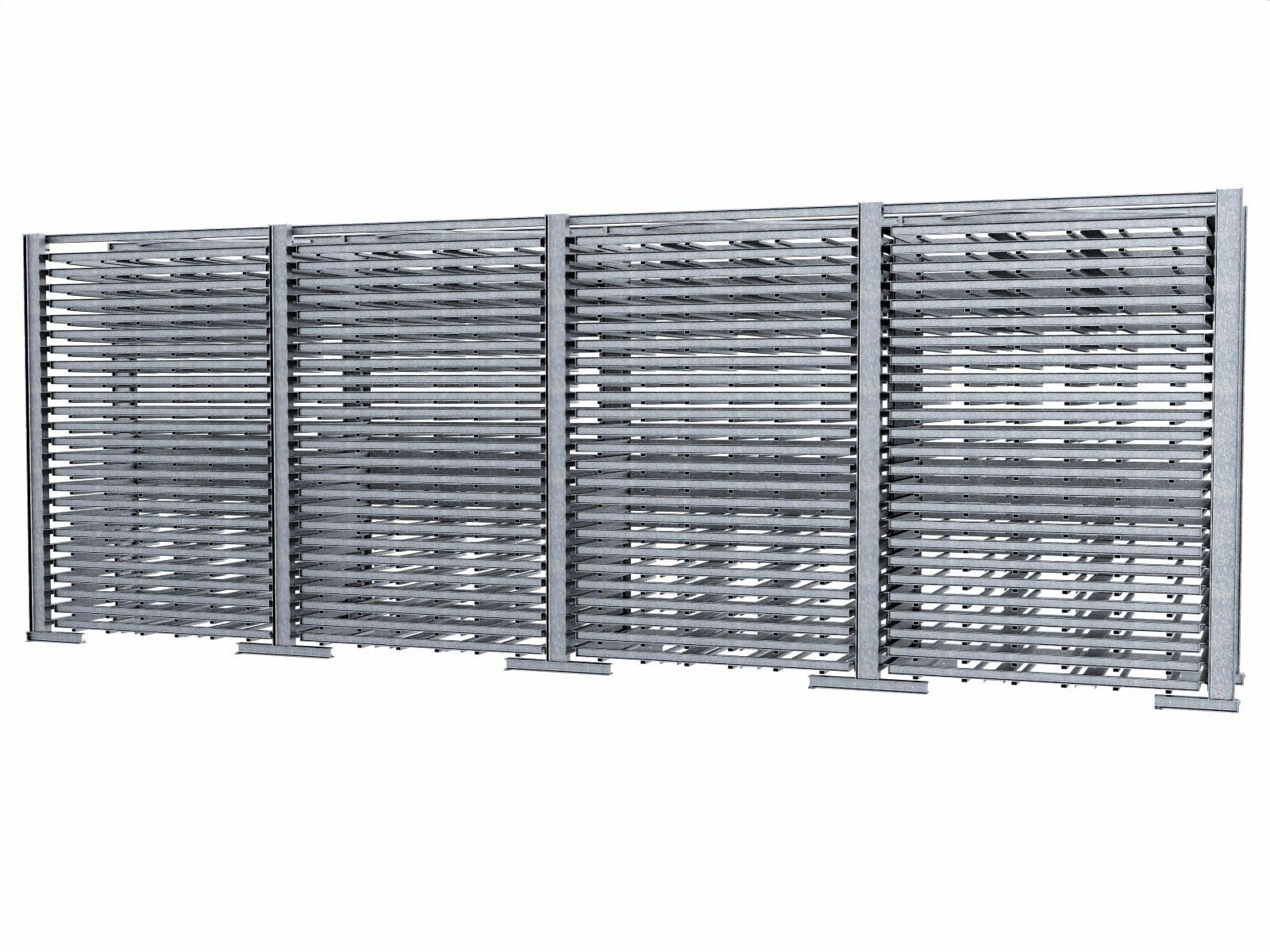

ShuttleTower® slide-in pallet system

The storemaster® Sheet metal storage system ShuttleTower® with the load carrier superFLAT stands for an exclusively highly compressed storage density to save valuable storage space. The extremely high operational safety during transport (slipping out) and storage is achieved by the impact-resistant all-round protection of the sheet metal package inside the load carrier superFLAT. The frame height is identical to the maximum height of the metal stack. Optional safety pins can be provided for higher stacks. An appropriate all-round clearance simplifies loading and also allows untrimmed sheets to be picked up, as well as the storemaster®-The open forklift shoes with raised entry dimension for the forks provide alternative loading by belt. The surface is permanently protected against impact and corrosion by hot-dip galvanising in accordance with DIN EN ISO 1461. The open forklift shoes with the increased entry dimension for the forks protect the forklift against loss of stability (risk of tipping) in the event of an unevenly distributed load contrary to BG requirements (tubular shoes only on special customer request).

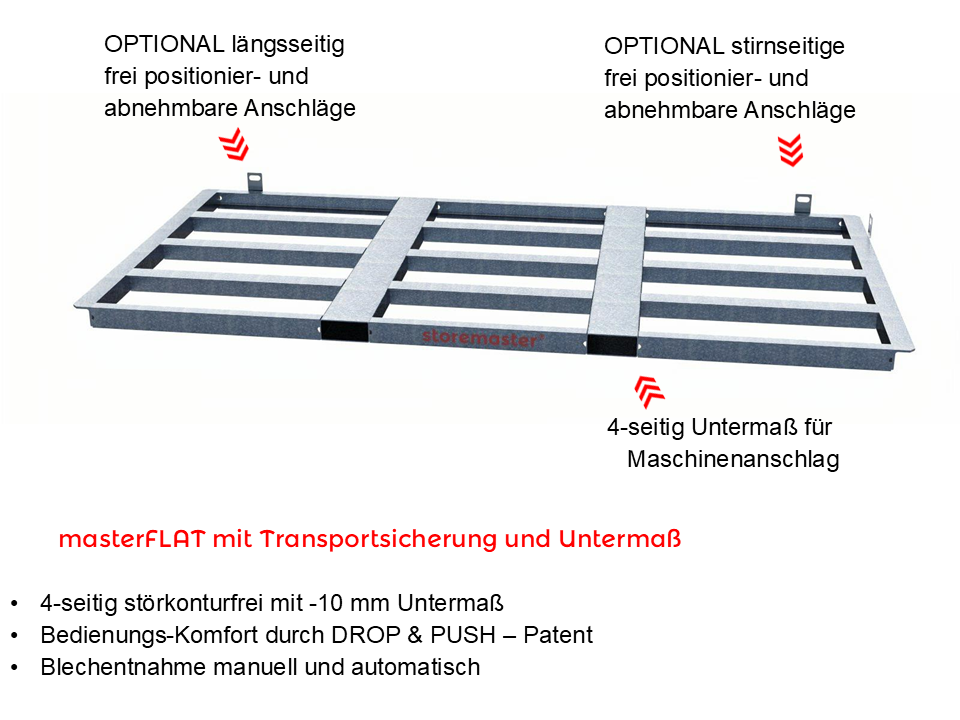

To remove a sheet from the stack of sheets by hand, the load carrier is placed on a stamping table (or PalEx) is set down - the load carrier lowers - the stack of sheets lies freely on four sides on 15 movable stamps of the stamping table - the topmost sheet can now be removed freely on all four sides in an ergonomically favourable manner without having to remove pins. Once the sheet stack has been removed, simply lifting the load carrier places it safely back in the cassette for transport.

The upright structure (tower load 150 t) in welded L and T upright-frame construction with inward-facing foot beams for rigid absorption of the diagonal forces in the longitudinal direction of the racking for a permanently stable vertical position of the uprights (6-disc stable) is the prerequisite for unlimited guaranteed functionality. In this way, diagonal braces at the rear can be dispensed with if there is a risk of them being destroyed by overlong forks.

The occasional need to adapt to changing shelf heights is made possible by the 75:75 mm rail plug-in grid.

In addition to the features mentioned above, the most important unique selling point for the user is the unique Drop & Push storage convenience patent with the positively guided angle-on-angle insertion in front of the front of the stored pallets. This eliminates the need for laborious threading into the compartment gap, while at the same time effectively preventing damage of any kind to the sheet metal package, uprights or system pallet thanks to a guaranteed safe, collision-free and time-saving storage process.

open forklift shoes:

- Optimum clearance as unobstructed entry height for the forks even when the forklift/pallet is tilted

- No jamming of the forklift forks => prevents the pallet from being pulled along when the forks are pulled out

- In accordance with UVV for securing the stability of the forklift truck with unevenly distributed loads

welded footbars:

- Permanently secure the vertical position of the shelving columns => unlimited functional guarantee

- Replace field assemblies at risk of destruction with forklift forks

- Optimise load distribution over a wide area, even with low floor quality

extended tower rails:

- for free movement of the pallet into the compartment-high space between the tower rails

- for placing the pallet brackets on the tower brackets in front of the pallet front, even when the forklift/pallet is tilted

- Angle-on-angle guide for collision-free pallet insertion, optimised by entry slopes

- for an excavation only a few millimetres high when removing the pallet

- Shelf heights can be plugged in to adapt to changing usable heights

Advantages at a glance:

- Highest bearing density in tower bearings

- Convenient storage thanks to Drop & Push patent

- Angle-on-angle guide for additional safety

- Shelf heights can be changed as required thanks to plug-in grid

- Hot dip galvanising increases durability

- Open forklift shoes for easy entry

The highlight: automatic tray removal:

- with patented stampmaster lift table (storemaster®-innovation)

- for e.g. sheetmaster liftmaster loadmaster byloader etc.

- 3-fold effect due to charge carriers superFLAT

- Universal use on all laser machines

- Unrivalled highest storage density

- Greatest safety comfort worldwide

- free of any interfering contours (analogous to wooden pallet)

- Free from fixed or temporary stops

- Precise reference point positioning

- Use of wooden pallets alternatively

Designs of the ShuttleTower®:

- Single tower or as a row of towers

- all sheet metal formats from 2,000 x 1,000 mm to 6,000 x 2,000 mm

- up to 5 t load capacity

- Compartment grid from 150 mm

- Maximum tower height 9 m

Various customisation options:

- Outdoor version with roof and wall

- Completely hot-dip galvanised for more weather resistance

- Selection of the appropriate load carrier provides additional variation options

We have compiled the following downloads for this product:

Practical system extensions and accessories for the ShuttleTower®

Smart extensions and additions to the ShuttleTower® Sheet metal storage compact system is the all-round solution for modern sheet metal storage in modern sheet metal processing companies ... ShuttleTower® means flexibility in sheet metal storage technology with future potential. The standard accessories at a glance:

Passendes Zubehör

-

MultiPlate® offcut shelf

4.500,00€The small sheet metal warehouse

storemaster® Innovation 2022excl. VAT

To the details -

PalEx® classic

from 2.650,00€Depalletiser and cassette loader

storemaster® Innovation from 1997excl. VAT

To the details This product has multiple variants. The options may be chosen on the product page -

Flexibolo® BP

from 3.725,00€Sheet metal parcel transport trolley

excl. VAT

To the details This product has multiple variants. The options may be chosen on the product page -

StoreKeeper® Smart App

2.500,00€Universal warehouse management software

excl. VAT

To the details

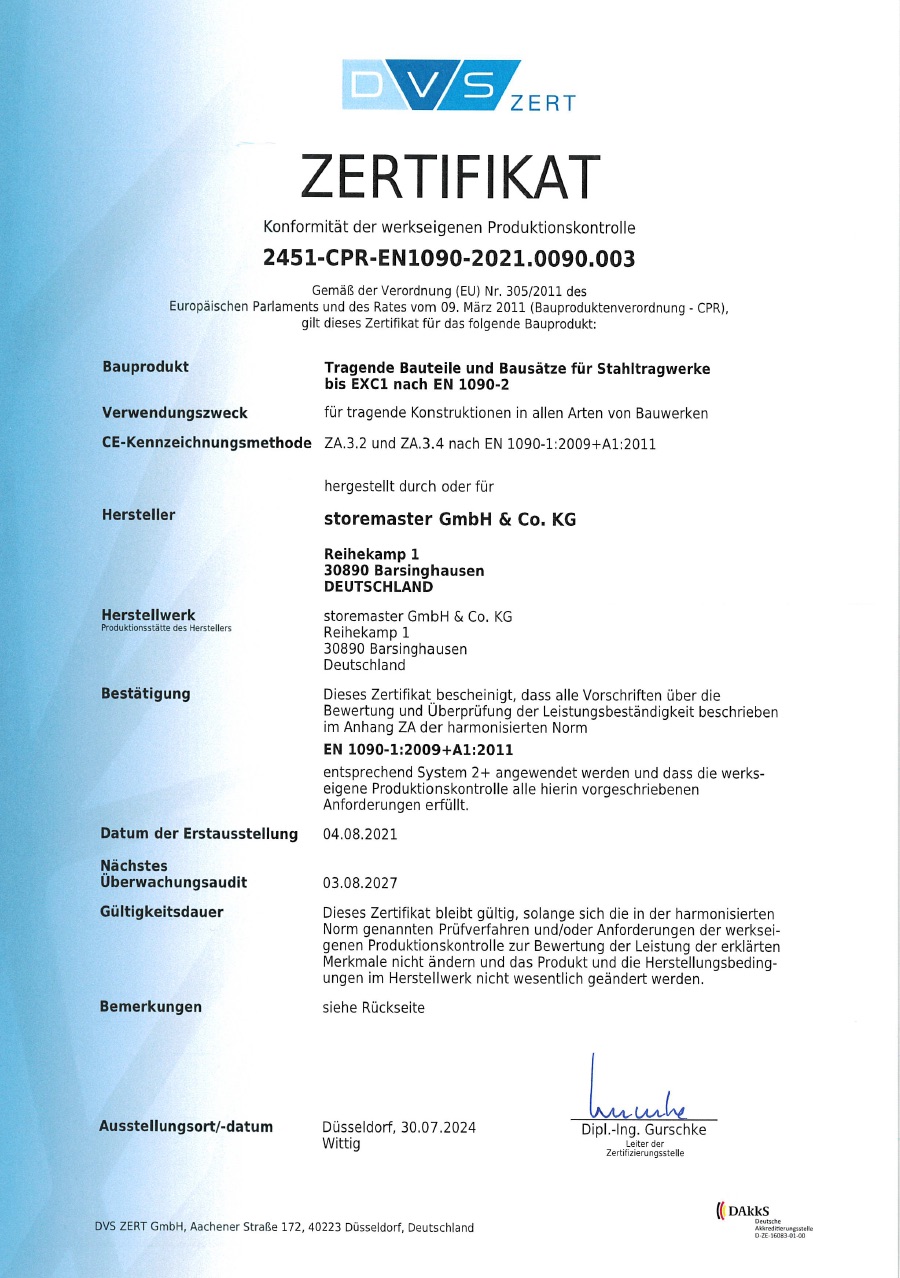

Manufacturer information

storemaster GmbH & Co. KG

Reihekamp 1

30890 Barsinghausen

Germany

Person responsible for the EU

Dipl.-Ing. Dieter Karl Artur Paul

Does not apply to already reduced offers.

You can find more information on calculating quantity discounts and payment methods here:

Free delivery within Germany from goods value ≥ 5000€ CIP

Within the EU EXW ex works

Outside the EU EXW ex works plus 5% foreign flat rate

Contact us for customised solution concepts: