Sheet metal bearing

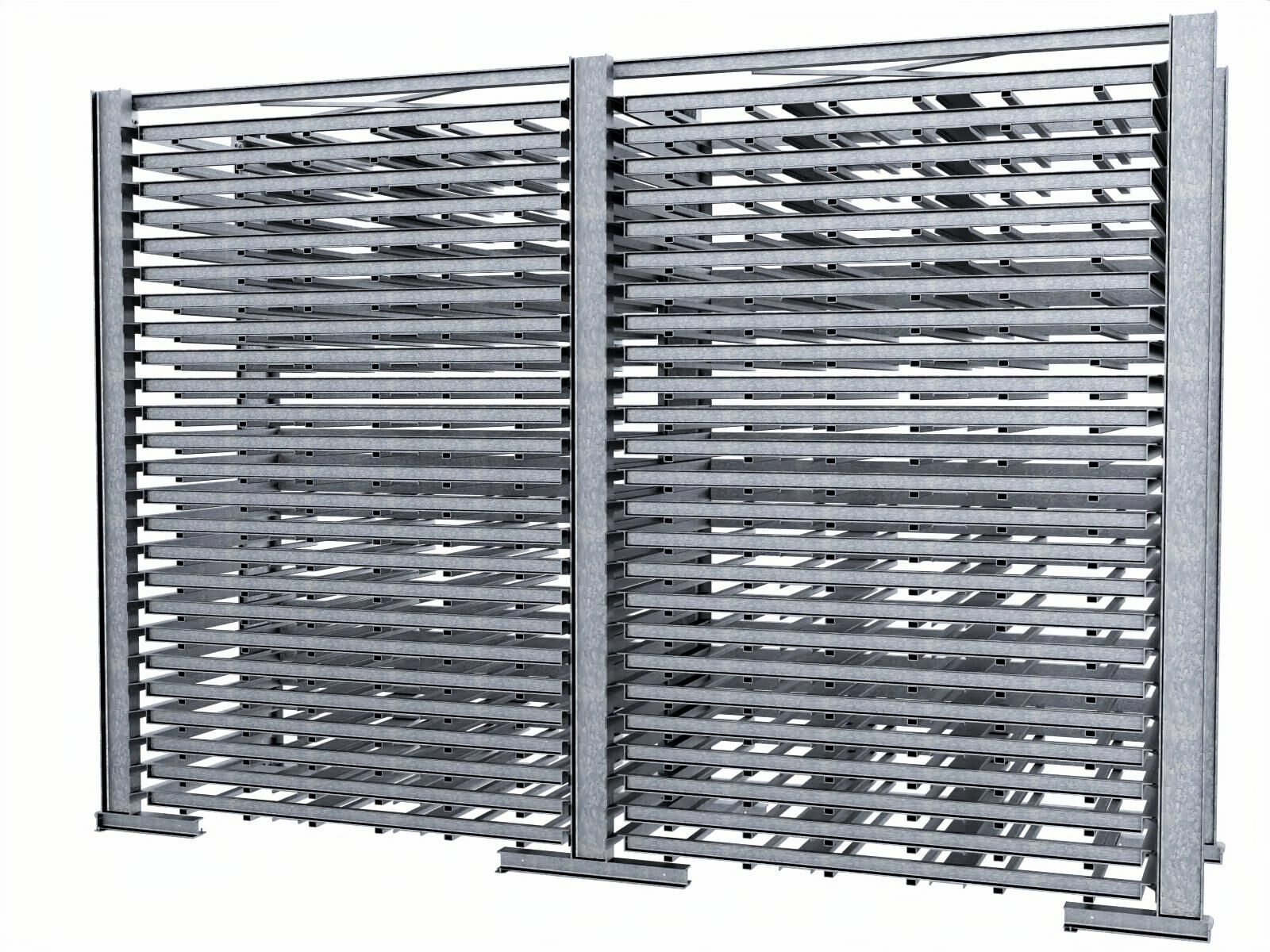

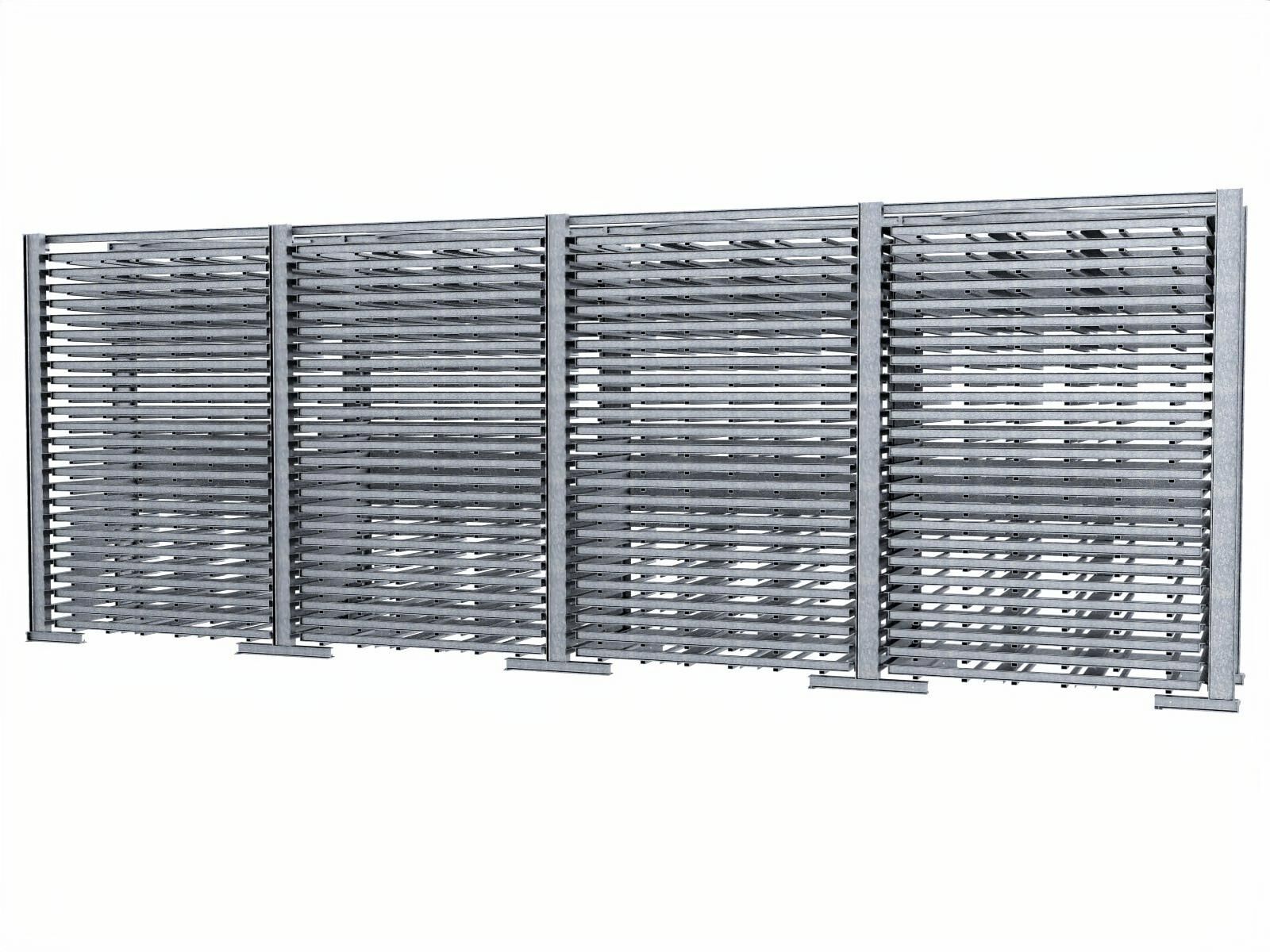

ShuttleTower® cassette sheet metal storage system The original from 2001 with the highest storage density on the market

with the storemaster® Slide-in patent

prof. steel construction engineering

(rigid connections, 5-fold kink safety)

Resistant to forklift impacts

20 years warranty

from 5.793,00€

excl. VAT

Delivery time: 10-12 weeks

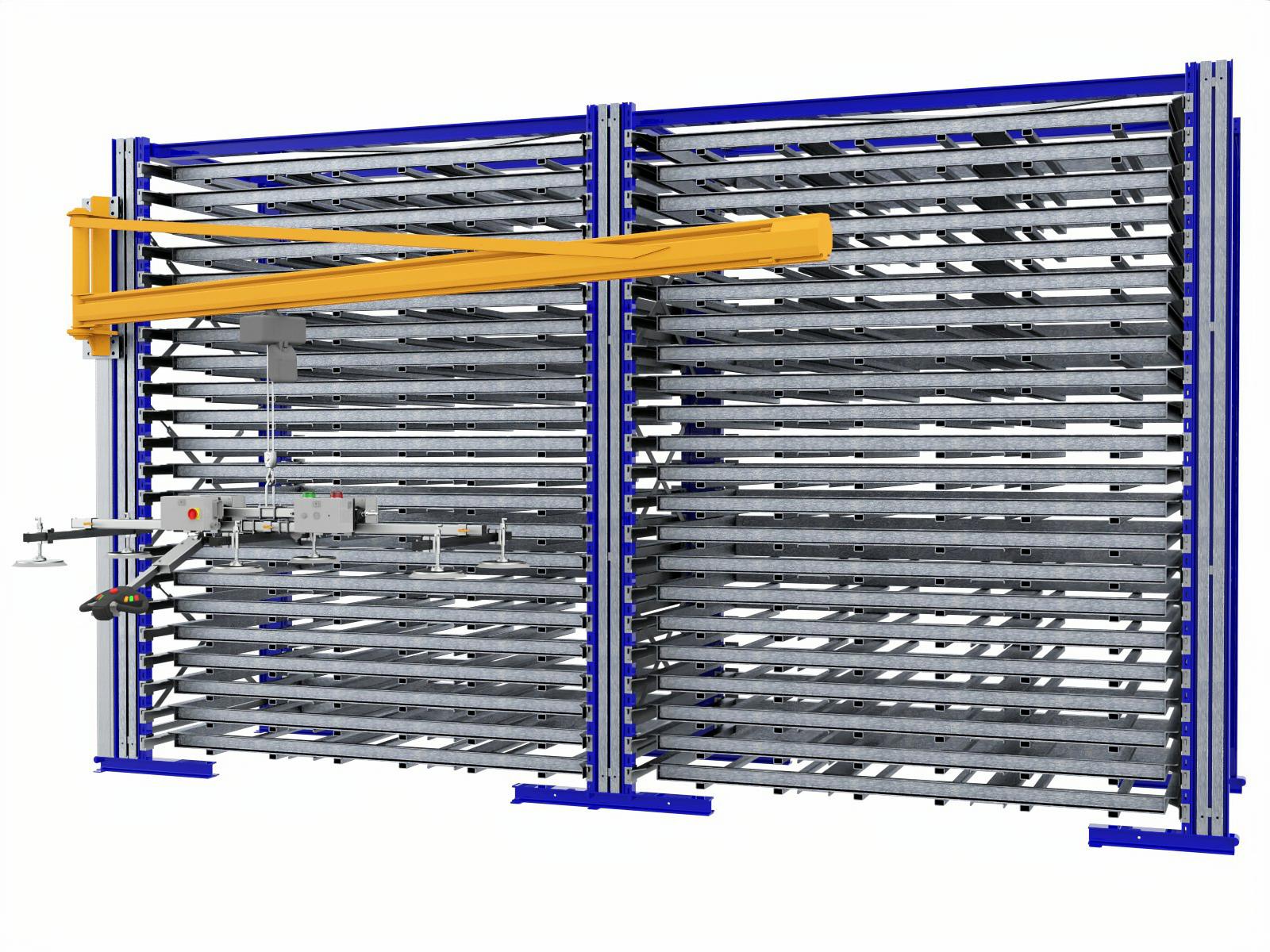

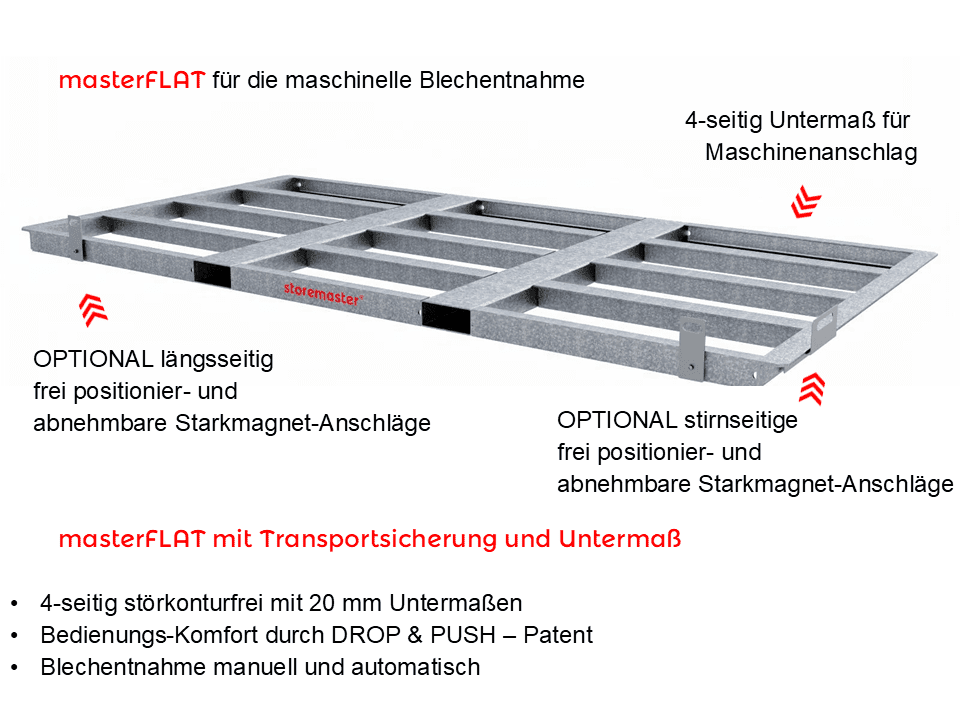

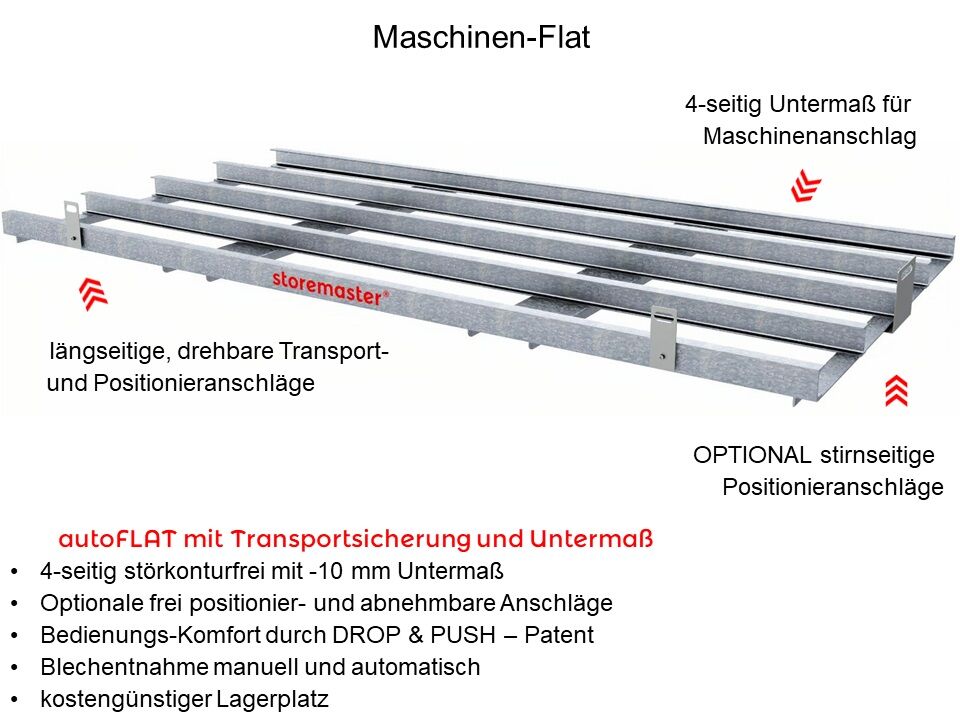

With the collision-free storemaster® Angle-on-angle constrained guide comfort insertion patent and the storemaster® Safety retraction stroke of approx. 200 mm. BG safety thanks to rigid connections and 5-fold safety against buckling (incl. 1st shelf test in accordance with DIN EN 15635). For manual tray removal with load carriers superFLAT-classic or superFLAT-plusas well as for semi-automatic and fully automatic sheet feeding on all machines with load carriers masterFLAT or autoFLAT with 20 mm undersize in length and width for the stop technology, suitable for: Trumpf Liftmaster, Sheetmaster, Loadmaster, Bystronic, Amada, automatic storage towers. Design, arrangement, storage density and capacity of the towers in individually demand-optimised combinations. The uprights and load carriers are resistant to forklift impacts thanks to the use of hot-rolled solid steel profiles in an impact- and corrosion-resistant, hot-dip galvanised design. Maximum durability and sustainability thanks to Quality No. 1.

➠ Optionally with integrated crane vacuum technology.

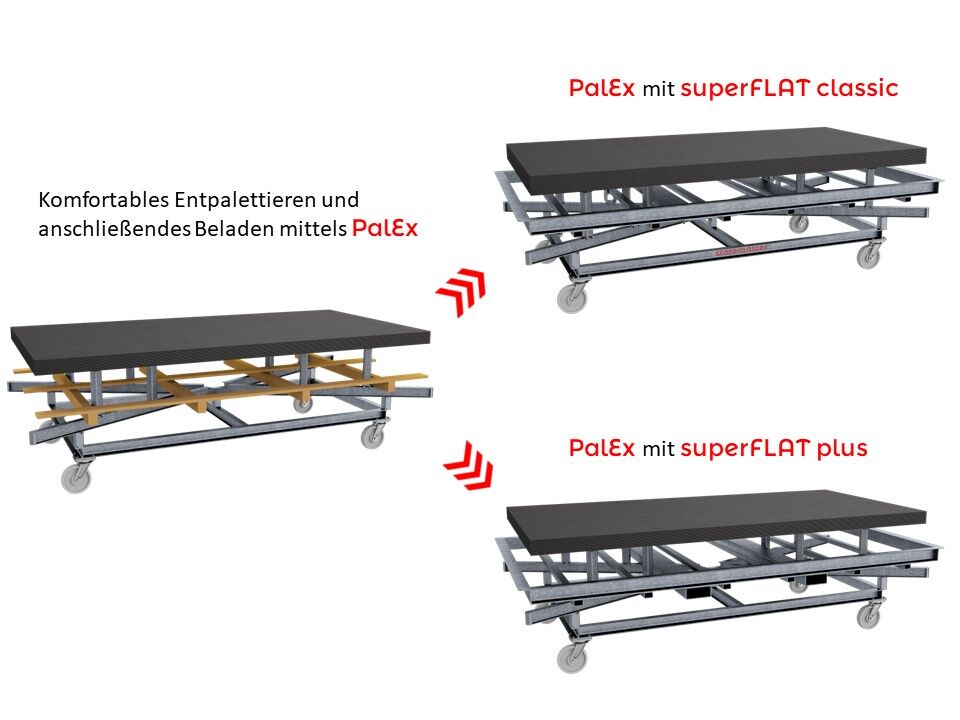

PalEx® 25 years of success story

- for patented depalletising and loading of the superFLAT-Load carrier

FlatLoader®

- for the patented loading of the masterFLAT- and autoFLAT- Load carrier

- for a quick sheet metal type change on automatic storage towers

Load carrier suitable for:

- Liftmaster, Sheetmaster, Loadmaster

- Bystronic, Amada, automatic storage towers

- Manual crane vacuum sheet removal technology

ShuttleTower® slide-in pallet system

Unique selling propositions of the company, which has been

from storemaster® developed sheet metal bearing cassette system.

- The extremely high storage density saves valuable storage space: shelf heights from 150 mm.

- Welded foot beams in the longitudinal direction of the shelving prevent the shelving uprights from tilting at a later date, even when installed on interlocking paving stones, asphalt, etc. without tension-proof floor anchoring (permanent tilt resistance).

- The special exclusivity of the system is the Drop&Push patent - the cassette flat does not have to be painstakingly and skilfully threaded into the free narrow compartment gap, Instead, it can be set down collision-free in front of the front of the stored pallets with its front-side frame angles on the extended upright support brackets and then guided angle-on-angle until it stops on the abrasion-resistant galvanised guide brackets.The 10 mm high legs of the frontal cassette support brackets have the full shelf height between the extended insertion brackets of the upright frame available as free lifting clearance - entry funnels provide additional centring to facilitate this, so that safe, tilt-free insertion is guaranteed even when the pallet is tilted on the forklift fork.

- Only the frame construction of the uprights consisting of base beams welded in the longitudinal direction and a rigid head beam construction makes it possible to dispense with the diagonal cross bay bracing otherwise required to stabilise a conventional rack construction, which is not possible in the front area anyway and is exposed to destruction from overlong forks at the rear.

- As with a wooden pallet, the forklift shoes are left open at the bottom to maximise the entry height for the forks, which makes it considerably easier to pick up the load carriers during retrieval, even when the forklift is in an inclined position. Unfortunately, tubular shoes must be used for machines with automatic sheet pick-up.

- The stud frame carries 150 tonnes with 2-fold safety

- The frame design of the cassette flats provides the sheet metal package with transport safety in all directions.

4 pages. - The deep web design and the clear oversize of the flats also allow the sheet metal packs to be stored using load belts, the insertion of pins for packs with excess height and the storage of unedged sheets with oversize.

- The durable support profiles of the flats made of solid moulded steel are permanently impact-resistant.

- Paint damage to the flats is ruled out by an impact-resistant hot-dip galvanising process, which also makes outdoor use possible with a 30-year corrosion protection guarantee.

- Various special applications are possible, e.g. skid design for roller conveyors, storage of non-depalletised sheet metal packages, universal stacking device for changing formats and package overheights within a load carrier.

- The forklift drive-in shoes are adapted to the fork spacing and fork width of the forklift fork.

- The patented depalletiser PalEx® enables depalletising and flat loading within a few minutes; the PalEx® excellently suited.

- Crane vacuum sheet removal technology can be integrated into the storage towers with little effort.

- En bloc stacked pallets, drawer and exchangeable pallet system blocks can be easily inserted in the floor area of the towers.

- The extensive range of accessories such as programmable, particularly eye-catching LED compartment displays, chaotic RFID storage using transponder reader technology, barcode kits, magnetic number plates for fixed location storage, warehouse management programme storekeeper®smart especially for sheet metal storage, coils, slit strip rings, bar material, but also for any other piece goods including ERP interface, etc. characterises the universality of the system.

We have compiled the following downloads for this product:

Practical system extensions and accessories for the ShuttleTower®

Smart extensions and additions to the ShuttleTower® Sheet metal storage compact system is the all-round solution for modern sheet metal storage in modern sheet metal processing companies ... ShuttleTower® means flexibility in sheet metal storage technology with future potential. The standard accessories at a glance:

Passendes Zubehör

-

MultiPlate® offcut shelf

4.500,00€The small sheet metal warehouse

storemaster® Innovation 2022excl. VAT

See details -

PalEx® classic

from 2.650,00€Depalletiser and cassette loader

storemaster® Innovation from 1997excl. VAT

See details Dieses Produkt weist mehrere Varianten auf. Die Optionen können auf der Produktseite gewählt werden -

Flexibolo® BP

from 3.725,00€Sheet metal parcel transport trolley

excl. VAT

See details Dieses Produkt weist mehrere Varianten auf. Die Optionen können auf der Produktseite gewählt werden -

storekeeper®smart warehouse management software

4.990,00€Complete material flow can be mapped, short training period, one-off company licence

excl. VAT

See details

Herstellerinformationen

storemaster GmbH & Co. KG

Reihekamp 1

30890 Barsinghausen

Germany

Verantwortliche Person in der EU

Dipl.-Ing. Dieter Karl Artur Paul

Frequently asked questions about sheet metal bearings

Do you have any questions about our sheet metal bearings? Our FAQs provide clear answers on topics such as modularity, load capacity, customisation options and installation requirements. Find out how our system can optimise your storage processes and what advantages it offers for your specific needs. What criteria should you use to select a sheet metal storage system and how does it actually work? Find out that and more here.

Does not apply to already reduced offers.

You can find more information on calculating quantity discounts and payment methods here:

Free delivery within Germany from goods value ≥ 5000€ CIP

Within the EU EXW ex works

Outside the EU EXW ex works plus 5% foreign flat rate

Contact us for customised solution concepts: