MasterTower® classic

Sheet metal storage drawer rack

with integrated crane vacuum technology

Pull-out rail walls without ground contact

Manual extract and electric

Prof. steel construction with 20 year guarantee

The storemaster® Original from 2000

from 13.267,00€

excl. VAT

Delivery time: 8-10 weeks

First one-man sheet metal handling compact station without external crane or forklift traffic

... one storemaster®-Innovation from the Year 2000 with 20 year guarantee (DIN EN ISO 9001 suitable)

➠ Basic drawer unit ➠ TwenTower® classic

Delivery: free delivery within Germany

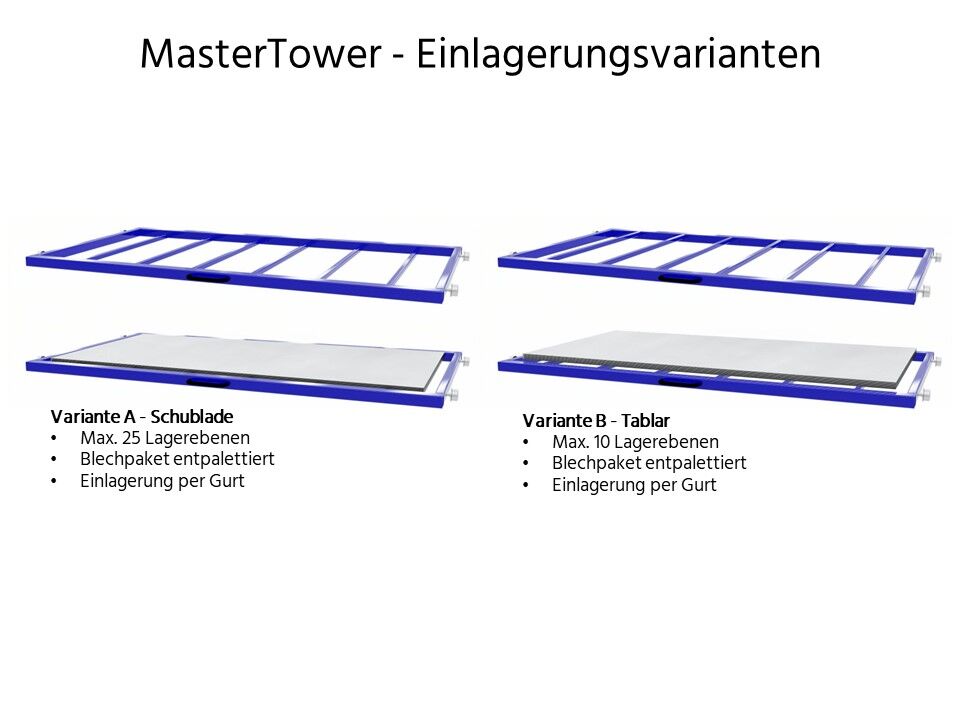

First sheet metal storage drawer system for the wood-free Storage more complete Sheet metal packages, instead of Sheet metal for sheet metal

- one storemaster®-Innovation from the Years 1996 with 20 year guarantee (DIN EN ISO 9001 suitable)

storemaster® Unique selling proposition-Features:

➠ automatically acting safety devices according to UVV

➠ without UVV-incompatible manual Locking devices

➠ Patent drawer safety catch

➠ Swivelling drawer runner panels under load without ground contact Protects sealed floors and surface coatings

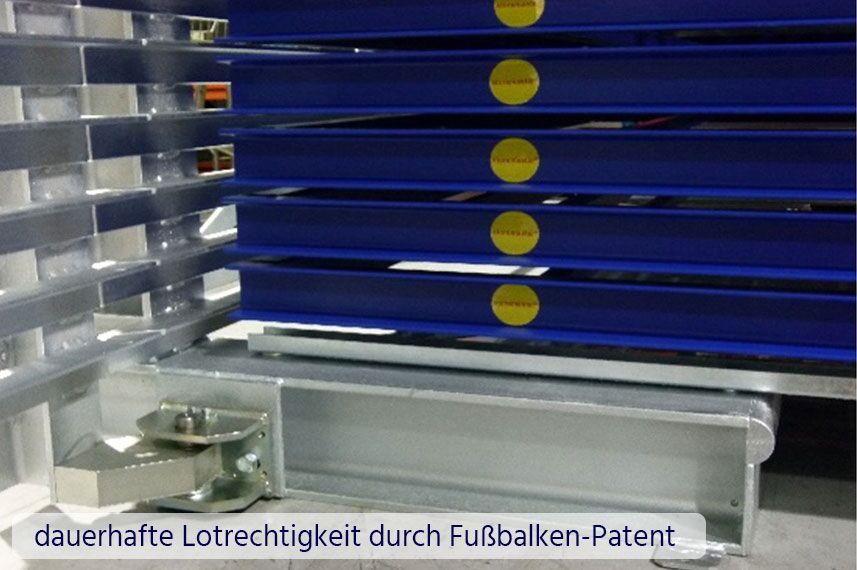

➠ Suitable for the Installation on sloping floor levels and Any soil conditions

➠ Installation Without foundation through foot beam load distributor

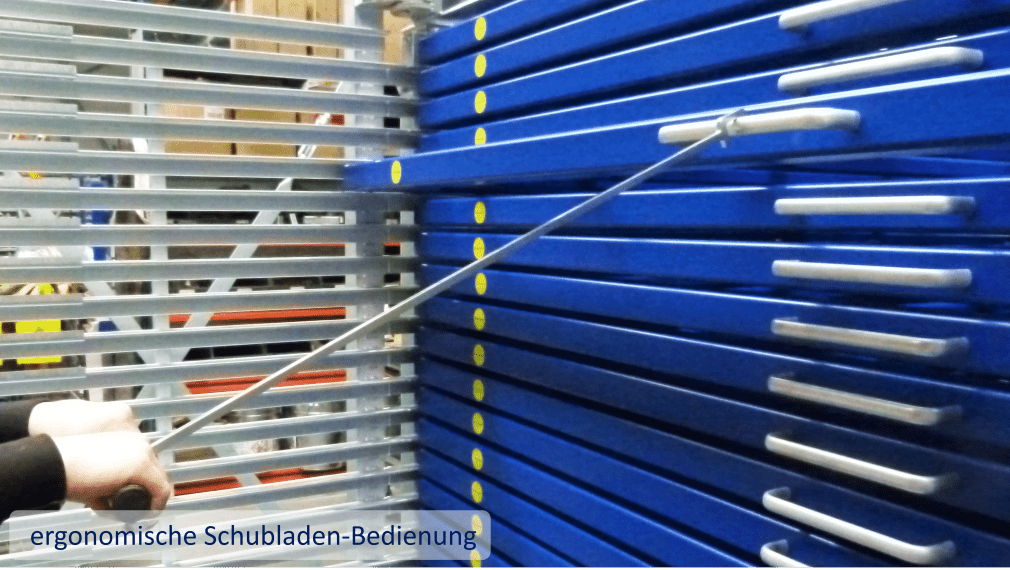

➠ Functional accessories incl.: storeboy mobile step and handling hooks for ergonomic operation at any height, as well as composite anchors for the required, tension-resistant fixing of the equipment to the hall floor

MasterTower® classic - The leading sheet metal storage system with electric crane vacuum technology

The MasterTower® classic is that World's best-selling sheet metal bearing and a Investment for generations. With its self-supporting drawer runner walls and a load capacity of up to 3,000 kg per drawer it is ideal for companies that Efficient, safe and space-saving sheet metal storage would like. The Crane vacuum technology enables a Simple one-man operation and makes the MasterTower® the perfect Storage tower for trays with tray removal.

Maximum efficiency thanks to patented storemaster® technology

✔ Electric drawer runners - Reduced operating forces for effortless handling

✔ Automatic drawer fixing - Automatic locking in rest & working position

✔ Self-supporting pull-out runner walls - No floor contact, no damage to floors

✔ Torsion-resistant L-frame system - Permanent perpendicularity without diagonal braces

✔ Optimised for forklifts & crane systems - Perfect for automatic tray removal

Technical highlights of the MasterTower® classic

🔹 Patented flange groove guide for 100 % UVV-compliant fall protection system

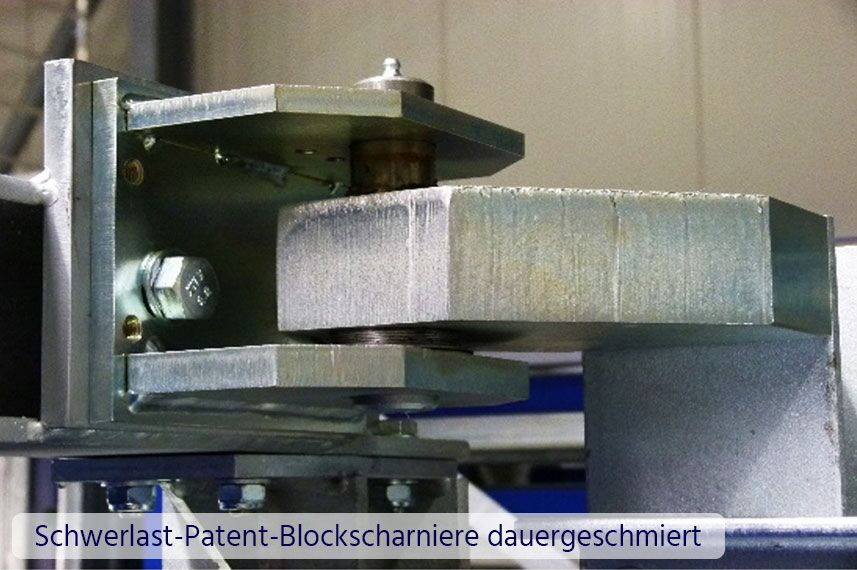

🔹 High-capacity drawers (up to 3,000 kg per level) with precise block hinge lock

🔹 Thrust spring servoPatent - Facilitates extraction even with heavy loads

🔹 Combined storage possible - Storage with or without wooden pallet

🔹 Automatic fixing of swivelled-out rail walls through Strong magnet adhesion

🔹 Heavy-duty solid steel flanged castors With double ball bearings for maintenance-free operation

📌 Space-saving solution for maximum storage capacity:

✔ Up to 25 drawers at a height of just 2 metres

✔ 100 % Pull-out drawer for full accessibility

✔ Push-through safety device for double-sided tray removal

Ideal for storage in automatic sheet metal storage towers

The MasterTower® classic is compatible with all common sheet metal storage systems like Bystronic, Amada, Liftmaster & Loadmaster and can be seamlessly integrated into automated production processes.

💡 Expandable with TwenTower® - Simple addition of professional Steel construction with integrated crane column.

Sustainable, safe & economical

🌍 Wood-free material movement - No fire load, no disposal costs

🔹 Hot-dip galvanised running rails - 10 times more abrasion-resistant than painted surfaces

🔹 Long service life - 20-year functional guarantee for maximum investment security

🔹 Dirt-free storage - Ideal for Cleanroom applications & sensitive materials

The MasterTower® classic offers a Future-proof, efficient and ergonomic solution for sheet metal storage in industry & trade.

🚀 Enquire now & take sheet metal storage to a new level!

We have compiled the following downloads for this product:

Passendes Zubehör

-

PalEx® classic

from 2.650,00€Depalletiser and cassette loader

storemaster® Innovation from 1997excl. VAT

See details Dieses Produkt weist mehrere Varianten auf. Die Optionen können auf der Produktseite gewählt werden -

Flexibolo® BP

from 3.725,00€Sheet metal parcel transport trolley

excl. VAT

See details Dieses Produkt weist mehrere Varianten auf. Die Optionen können auf der Produktseite gewählt werden -

LoadingBeam

from 4.986,00€Loading traverse for the drawer

and optional cassette loadingexcl. VAT

See details Dieses Produkt weist mehrere Varianten auf. Die Optionen können auf der Produktseite gewählt werden -

HandlingMaster

9.006,00€The vacuum traverse in comfort version

Tableau operation with sheet separatorexcl. VAT

See details

Herstellerinformationen

storemaster GmbH & Co. KG

Reihekamp 1

30890 Barsinghausen

Germany

Verantwortliche Person in der EU

Dipl.-Ing. Dieter Karl Artur Paul

Does not apply to already reduced offers.

You can find more information on calculating quantity discounts and payment methods here:

Free delivery within Germany from goods value ≥ 5000€ CIP

Within the EU EXW ex works

Outside the EU EXW ex works plus 5% foreign flat rate

Contact us for customised solution concepts: